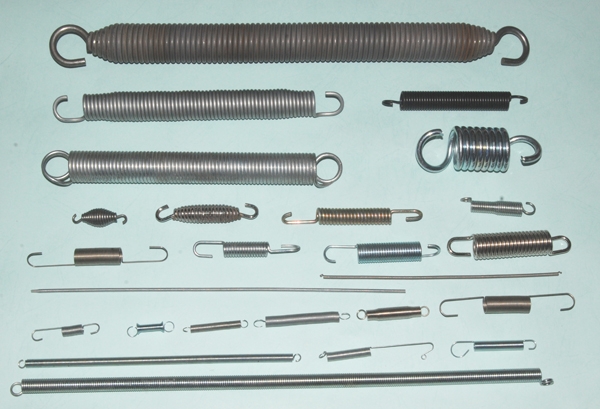

Extension Spring

Product Introduction

|

We provide precision extension springs which absorb and store energy by offering resistance to a pulling force. The precision extension springs are made from round wire and are close wound with initial tension. The part of extension applications include tape cassette players, balance scales, garage doors, washing machines and applications which requiring various types of tensioning devices. Various types of ends are used to attach the extension spring to the source of the force. Unlike compression springs, precision extension springs don't have a solid stop to prevent overloading. Because of this design stress levels are lower for extension springs than for compression. Feature:

|